Please do not hesitate to contact us if you have any question and enquiry.

Contact UsThe safety and quality of pharmaceutical products are related to everyone's health and directly affect people's livelihood and social stability.

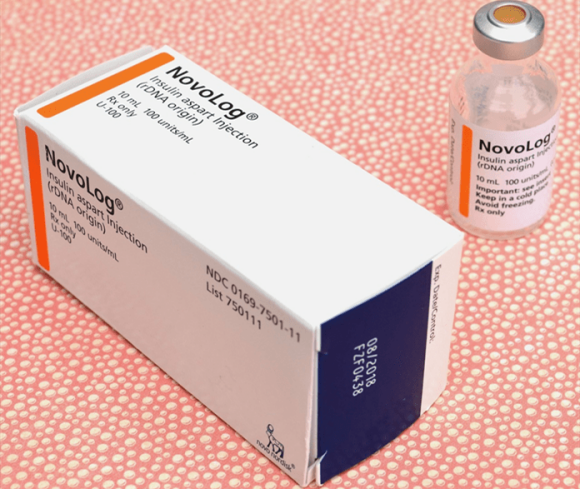

The safety of pharmaceuticals lies not only in the production process but also in the strict control of pharmaceutical cold chain logistics. But what exactly is the so-called pharmaceutical cold chain logistics? What are the key points to note?

Pharmaceutical cold chain logistics refers to the refrigerated pharmaceutical transport system engineering for the purpose of national disease prevention, diagnosis and treatment to ensure that pharmaceutical products are always within a specific temperature range in all aspects of the chain from the factory, storage, transportation, distribution, sales to consumers, to escort pharmaceutical products and ensure their quality and safety. It is necessary to ensure the information sharing and full temperature control of pharmaceutical circulation, so as to realize the visualization and traceability of the whole process.

Among them, refrigerated trucks, incubators, and temperature and humidity indicators are the three main points that cannot be ignored in pharmaceutical cold chain logistics.

A refrigerated vehicle refers to a vehicle with an insulated compartment and a refrigeration device. Among them, the structure of medical refrigerated vehicles is basically the same as that of ordinary refrigerated vehicles such as food and dairy products. They are all composed of special vehicle chassis running parts, heat insulation compartments, refrigeration units, and temperature monitors in the compartments. They have automatic temperature control, display, storage, read temperature monitoring data, refrigeration system failure remote and local real-time alarm and other functions.

Cold chain insulated box is a professional equipment for refrigerating pharmaceutical products in the medical industry, mainly used for the preservation and transportation of drugs, reagents, vaccines, blood, etc. As a device for transporting and storing special temperature biological products, the medical insulated box has high requirements for the temperature and humidity data in the box.

In the process of cold chain logistics transportation, temperature and humidity have a great impact on pharmaceutical products. Higher or lower than the standard temperature and humidity of pharmaceutical products will affect their quality and safety. Among them, temperature-sensitive drugs are likely to cause drug denaturation and failure. As the demand for real-time monitoring of temperature and humidity in the cold chain transportation of medicines is getting higher and higher, the temperature and humidity indicators also play an irreplaceable role. During the transportation process, the temperature and humidity indicators can effectively prevent the risk of "broken chain" in cold chain transportation by automatically monitoring and recording the temperature and humidity in real time, so as to ensure the quality of pharmaceutical products to the maximum extent and reduce loss.

(1) The equipment can use a large-size LCD screen, which can display real-time temperature and humidity values, remaining power, the number of stored data and system time, and can intuitively monitor the temperature and humidity values during loading and unloading.

(2) It has an alarm function because it has a built-in buzzer. Once the value exceeds the limit, it can send a high-decibel alarm to remind the supervisor to take measures to keep the temperature within the specified range;

(3) It has the function of recording. The time from start to stop of equipment recording can be set. If multiple recorders are used in one transportation, it can ensure that all equipment starts and ends recording at the same time to ensure data integrity unity;

(4) Cold chain logistics companies can export the stored data in EXCEL, TXT, PDF and other formats through a USB cable to make reports to customers.

(5) It adopts a large-capacity rechargeable lithium battery, which can be used continuously for one year on a single charge, saving the trouble of charging before use.

AKS provides a series of temperature monitoring solutions, low cost and easy to use, and various specific temperature thresholds for cold chain monitoring.

If a detailed record is required, an electronic temperature data logger is a better choice, with the programmable alarm levels, and alarm indicator light or real-time LCD display, efficient solution for shipments. For any need for temperature and humidity Indicators, kindly get in touch with us today!

By continuing to use the site you agree to our privacy policy Terms and Conditions.