Please do not hesitate to contact us if you have any question and enquiry.

Contact UsIn the fast-paced world of global logistics, ensuring that goods arrive in perfect condition is no longer optional—it's a fundamental expectation. Among the most critical factors affecting product integrity during transit is temperature control. Whether you're transporting frozen foods, life-saving medications, or high-value electronics, even minor deviations in temperature can lead to spoilage, performance failure, or regulatory non-compliance. This is where temperature monitoring devices become essential. However, not all devices serve the same purpose, and choosing the right one requires an understanding of the shipping scenario and the technical options available.

Temperature monitoring devices track, record, and sometimes transmit temperature data throughout the shipping process. Their primary role is to ensure that cargo remains within its required temperature range, but their impact extends much further. These tools provide traceability, strengthen accountability, and help companies demonstrate compliance with industry standards such as GDP (Good Distribution Practice) or HACCP (Hazard Analysis and Critical Control Points).

Thanks to innovation and digital transformation, monitoring devices have evolved beyond basic loggers. Now, businesses can choose from a range of solutions offering live updates, cloud storage, and integration with GPS and other sensors. Yet with this variety comes the challenge: selecting the appropriate device for a specific shipping need.

Temperature monitoring devices fall into several distinct categories. Each type offers unique benefits depending on the goods being shipped, the route, the duration of transport, and the required level of data accuracy or accessibility.

| Device Type | Functionality | Best Use Case |

|---|---|---|

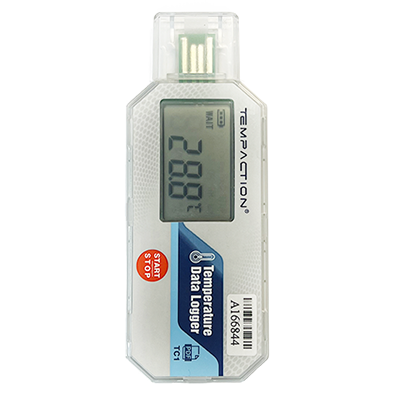

| Data Loggers | Records temperature over time for later review | Cold chain, pharmaceuticals, electronics |

| Wireless Temperature Sensors | Sends real-time temperature data via Bluetooth/WiFi | High-value or sensitive items needing alerts |

| Time-Temperature Indicators (TTIs) | Visual color change when exposed to excursions | Disposable packaging, low-budget shipments |

| Real-Time GPS + Temp Trackers | Combines GPS and temp tracking with alerts | Critical cold chain (e.g., vaccines) |

These options allow logistics professionals to tailor their monitoring strategy to each product's risk profile. For example, a vaccine shipment might require GPS-enabled real-time monitoring, while frozen meats for domestic delivery could be adequately served by data loggers.

Different industries face distinct temperature challenges, and each scenario demands a unique monitoring approach. Selecting the right device not only prevents losses but also builds trust with customers and regulators.

In the cold chain, consistency is king. Perishable goods such as seafood, dairy, and fresh produce must remain within a narrow temperature band from origin to destination. For these shipments, temperature data loggers are frequently used, particularly USB or PDF-enabled models that generate instant reports upon arrival.

However, many cold chain providers are moving toward wireless Bluetooth sensors that can be scanned via mobile apps at key checkpoints. These sensors streamline quality control and reduce reliance on paper-based documentation.

Pharmaceuticals, including vaccines, biologics, and temperature-sensitive drugs, require strict thermal control throughout transit. Here, real-time monitoring devices integrated with GPS provide a strong advantage. These systems not only ensure temperature remains stable, but also offer location-based data that supports chain-of-custody reporting and real-time intervention if thresholds are breached.

Additionally, many pharma shipments are monitored using validated devices that comply with WHO PQS standards or GDP guidelines. In this sector, data precision and audit readiness are non-negotiable.

Temperature can affect not just food or medicine, but also high-performance electronics. For instance, batteries, semiconductor chips, and sensitive circuit boards can malfunction if exposed to extreme cold or heat.

Wireless temperature sensors are an ideal solution for this sector, especially when combined with shock and tilt indicators. The integrated data helps pinpoint the moment—and the conditions—under which a product may have been compromised.

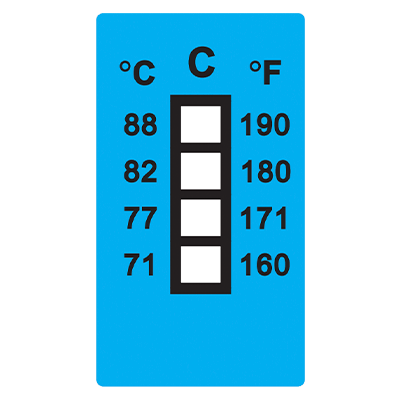

Consumer products that travel long distances—such as cosmetics, chocolates, and specialty beverages—also benefit from basic temperature monitoring. Time-Temperature Indicators (TTIs) are often used here. These single-use, adhesive-based indicators change color if exposed to critical temperature thresholds, offering a simple and budget-friendly method for validating handling conditions.

Though they don't provide digital records, TTIs are lightweight, tamper-evident, and easy to train handlers to use—making them a go-to tool for cross-border retail shipments.

Selecting the right device starts with understanding the specific needs of your shipment. Ask the following:

What are the temperature sensitivity and threshold limits of the cargo?

More sensitive products will likely require real-time devices or loggers with high accuracy.

Is the data needed immediately or after delivery?

If post-delivery review is sufficient, standard data loggers will do. For live monitoring, choose a wireless or GPS-integrated option.

What is the shipment duration and destination?

Long-haul or international shipments may require devices with longer battery life, cloud sync capabilities, or durable enclosures.

Do compliance requirements apply?

Pharmaceuticals, for instance, may require devices that meet WHO, EU, or FDA regulations, with secure audit trails and calibrated precision.

How important is cost-efficiency?

TTIs offer a cost-effective solution for basic needs, while advanced IoT devices come with higher upfront investment but added visibility.

By aligning your choice with these considerations, you'll ensure your monitoring solution is both effective and financially justified.

Rather than looking ahead, let's consider what is already reshaping temperature monitoring right now:

Cloud-Connected Dashboards: Devices that automatically sync data to online platforms allow logistics teams to monitor multiple shipments simultaneously, anywhere in the world.

QR Code and App Integration: Some newer models offer mobile app compatibility. A simple scan of the sensor provides temperature history, shipment ID, and alert logs—streamlining data access for both shippers and receivers.

Multi-Function Sensors: A growing number of devices combine temperature, humidity, shock, and tilt monitoring in a single unit. This not only reduces device clutter but also creates a complete picture of cargo handling quality.

Reusable Smart Packaging: Technologies like self-refrigerated smart boxes and reusable containers with built-in sensors are already in use in pharma and biotech logistics. These ensure end-to-end temperature control, especially in last-mile delivery scenarios.

These innovations enhance operational transparency and reduce administrative burden by minimizing manual report handling.

Once a shipment arrives, the next step is analyzing the data collected. A typical temperature logger provides a graph of temperature fluctuations, time-stamped to align with your transport logs. If any temperature excursion occurred, the data allows you to trace exactly when and possibly why it happened.

More advanced systems send alerts during transit, helping logistics teams take immediate corrective actions such as switching cooling units or rerouting shipments. Dashboards often visualize trends over time, highlighting carriers or routes with consistent issues—an invaluable asset in refining logistics strategies.

In regulated industries, downloadable reports can be attached to batch records or used during audits to demonstrate compliance. In consumer-focused sectors, data transparency also helps build trust by proving product quality on arrival.

Choosing the right temperature monitoring device is not just about checking a box—it's about taking control of your supply chain. With so many options available, matching the right tool to the right scenario makes all the difference. From simple TTIs in consumer shipments to sophisticated GPS-integrated sensors for pharmaceuticals, every use case has a fitting solution.

At AKS, we specialize in providing third-party temperature and condition monitoring devices that are purpose-built for today’s complex logistics environment. Whether your needs involve cold chain pharmaceuticals, high-value electronics, or long-haul perishables, our range of shock, tilt, and temperature solutions are designed to give you full visibility and peace of mind throughout every shipment. With AKS, your cargo is not only tracked—it’s protected.

By continuing to use the site you agree to our privacy policy Terms and Conditions.