Please do not hesitate to contact us if you have any question and enquiry.

Contact UsIn today's global supply chain, the transportation and storage of temperature-sensitive products require precision and attention to detail. Industries like food, pharmaceuticals, and even the transport of vaccines rely heavily on maintaining the ideal temperature throughout the entire journey. This is where time-temperature indicators (TTIs) play a crucial role, offering a simple yet powerful solution for ensuring product integrity. Here’s an overview of how TTIs can optimize cold chain management, reduce waste, and maintain high product quality.

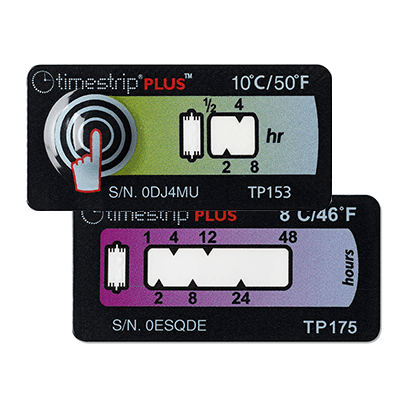

A time-temperature indicator (TTI) is a specialized device used to monitor the temperature of products during their transportation or storage. Unlike conventional thermometers that only measure the current temperature, TTIs provide a comprehensive record of temperature fluctuations over time. They capture the entire thermal history of a product, which is essential in determining if it has been exposed to damaging conditions.

For example, consider a pharmaceutical product that needs to remain within a strict temperature range. If the product is accidentally exposed to higher temperatures, the TTI will not only indicate the temperature but also how long it remained outside the acceptable range. This allows businesses to quickly assess whether the product is still safe for use or if it has been compromised, especially in critical industries like healthcare or food safety.

TTIs are designed to be user-friendly and cost-effective. Depending on the type, TTIs can use chemical dyes, liquid crystals, or bacterial fluids that change color based on temperature exposure. Once a product exceeds its designated temperature threshold, the TTI reacts—often with a noticeable color shift or dye flow, providing an immediate visual cue of temperature abuse.

The beauty of TTIs lies in their simplicity and efficiency. These indicators offer a clear and direct way of determining whether temperature control was maintained throughout the shipping process. TTIs are widely used in the food and pharmaceutical industries to monitor sensitive shipments like vaccines, ensuring that these products are delivered in optimal condition.

The benefits of integrating TTIs into cold chain logistics extend far beyond simply monitoring temperature. Here are some key advantages:

Time-temperature indicators are not limited to the transport of pharmaceuticals and food products. These devices have found widespread use in various industries where temperature control is essential. For example, TTIs are used by restaurants and food service businesses to ensure that food is stored at the proper temperature, and they are also employed in the logistics of sensitive goods like flowers, cosmetics, and electronics.

One of the most critical real-world applications of TTIs today is in the transportation of vaccines, especially with the emergence of the COVID-19 pandemic. Vaccines must be transported under strict temperature controls to maintain efficacy, and TTIs provide a reliable way to monitor and verify these conditions during transit.

The versatility of TTIs makes them suitable for a wide range of applications. Different products require different temperature ranges, and TTIs are designed to accommodate these needs. For example, TTIs may cover temperatures ranging from as low as -18°C (0°F) to as high as 37°C (99°F). This wide temperature spectrum ensures that all types of temperature-sensitive goods, from frozen food to pharmaceuticals, can be monitored effectively.

Some TTIs are specifically designed for more specialized uses, such as tracking the temperature of vaccines that need to be maintained at a consistent, precise temperature. These indicators are equipped with advanced features that allow them to track even minor deviations in temperature, ensuring the safety and efficacy of critical products.

The importance of time-temperature indicators in cold chain management cannot be overstated. They are an essential tool for maintaining the quality of perishable goods, improving supply chain transparency, and ensuring that regulatory requirements are met.

By incorporating TTIs into their cold chain processes, businesses can reduce waste, minimize spoilage, and make faster, more informed decisions regarding product integrity. Additionally, TTIs offer an efficient way to meet the rising demand for cold chain management solutions, especially in the pharmaceutical and food industries where the cost of damaged products can be extremely high.

If you're looking for reliable time-temperature indicators to enhance your cold chain operations, AKS offers state-of-the-art solutions tailored to your needs. Our ShockAction impact & tilt indicators, TempAction temperature & humidity recorders, and other temperature indicator solutions help businesses safeguard their products and optimize supply chain efficiency.

By choosing AKS, you are partnering with a trusted industry leader dedicated to providing innovative, simple, and efficient solutions for cold chain management. Our products ensure that your products are monitored at every stage, preventing temperature-related damage and helping you stay compliant with industry regulations. Contact AKS today to learn more about our solutions and how we can help you improve your cold chain logistics.

By continuing to use the site you agree to our privacy policy Terms and Conditions.